Why Optical Fibre Diameter Analyser Tools Are Important for Engineers

Unlock Accuracy: The Ultimate Guide to Optical Fiber Size Analyser Tools

Precise measurement of optical fiber diameter is important for boosting the efficiency and dependability of fiber optic systems. As we take a look at these tools, it comes to be apparent that the future of optical fibre analysis is progressing rapidly, increasing inquiries concerning just how these developments will certainly impact the sector.

Relevance of Optical Fibre Dimension

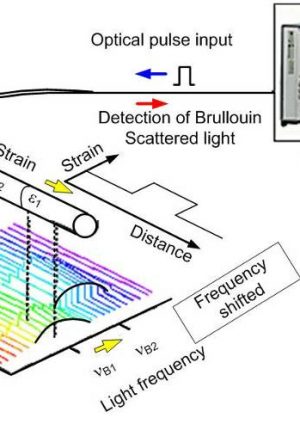

Precisely gauging optical fibre size is vital in guaranteeing optimal efficiency and dependability in communication systems. The diameter of optical fibers straight effects their light transmission abilities, impacting data transfer, depletion, and total signal stability. An exact measurement is important to preserve the wanted requirements for numerous applications, including telecoms, information transmission, and sensing innovations.

Irregular or incorrect fibre diameters can lead to enhanced losses and reduced effectiveness, inevitably endangering the efficiency of the entire communication network. In addition, variants in size can create problems in splicing and connecting fibres, leading to greater operational costs and possible system failings. Carrying out extensive measurement methods is important.

Types of Size Analyser Equipment

To attain trustworthy optical fibre measurements, different diameter analyser tools are utilized, each created to satisfy certain dimension demands and applications (optical fibre diameter analyser). These devices can be generally categorized into three main kinds: manual, semi-automated, and completely automated analyzers

Manual diameter analyzers are typically made use of in smaller operations or laboratories where precision is called for however manufacturing volume is reduced. They provide drivers straight control over the measurement process, enabling for careful modifications and verifications.

Semi-automated diameter analyzers improve efficiency by combining manual input with automated features. These devices frequently consist of easy to use interfaces that simplify the dimension process while still enabling driver oversight.

Completely automated diameter analyzers represent the peak of dimension technology. These advanced systems incorporate sophisticated sensors and software application to give real-time measurements with marginal individual intervention. They are excellent for high-volume manufacturing atmospheres, ensuring consistent accuracy and quick data collection.

Each sort of diameter analyser serves distinctive operational needs, making it important for users to very carefully assess their details requirements when picking the proper device for optical fiber dimension.

Key Features to Think About

When choosing an optical fibre diameter analyser, several essential attributes necessitate careful factor to consider to make certain ideal performance and dependability. Dimension precision is extremely important; look for devices that offer high-resolution readings, ideally in micrometers, to ensure accuracy in size evaluation. Additionally, the speed of measurement is important, specifically in production atmospheres where performance is important.

Another crucial feature is the calibration procedure, as a reliable analyser should provide simple calibration procedures to keep measurement honesty in time. The series of diameters the device can measure is also considerable; make certain that it accommodates the details fiber kinds relevant to your applications.

Portability could be a factor here to consider, specifically for fieldwork; compact and lightweight styles improve use in various setups. Moreover, user-friendly interfaces and software program compatibility can promote smoother operation and information evaluation.

Finally, consider the support and service warranty supplied by the maker; reputable customer support and thorough guarantee options can protect your investment and make sure long-lasting satisfaction. By concentrating on these functions, you can choose an optical fiber diameter analyser that fulfills your certain requirements and boosts your functional abilities.

Ideal Practices for Use

Efficient usage of optical fiber diameter analysers pivots on a comprehensive understanding of ideal methods that boost dimension reliability and accuracy. Initially, make sure that the analyser is calibrated properly prior to each usage. Calibration against recognized standards mitigates prospective errors and establishes a standard for succeeding measurements.

2nd, maintain a clean environment. Dirt, moisture, or pollutants on the analyser or the fiber's lenses can alter results. On a regular basis check and clean up both the fiber and the tools to keep optimal efficiency.

In addition, perform measurements at consistent temperature levels and humidity degrees, as environmental variables can influence results. File each measurement carefully, visit keeping in mind problems and any kind of abnormalities run into throughout the procedure.

Future Trends in Optical Fibre Analysis

As the demand for high-performance optical fibers continues to increase, developments in evaluation techniques are readied to transform the sector (optical fibre diameter analyser). Future patterns in optical fibre evaluation will likely be driven by enhanced automation and the combination of fabricated knowledge (AI) and artificial intelligence (ML) innovations. These advancements promise to boost data precision, minimize evaluation time, and make it possible for real-time monitoring of fibre quality

Furthermore, the growth of portable and user-friendly analysis tools will facilitate on-site evaluations, enabling better flexibility and effectiveness in manufacturing environments. Enhanced imaging technologies, such as high-resolution imaging and spooky analysis, are anticipated to give much deeper insights right into fiber attributes, allowing suppliers to optimize their processes even more.

In addition, as industries progressively welcome sustainability, there will be a promote environment-friendly materials and approaches in optical fibre manufacturing. This shift will require new analytical approaches to analyze the efficiency and long life of these products under varying conditions.

Final Thought

Precise dimension of optical fibre diameter is essential for maximizing efficiency and ensuring dependability in interaction systems. Continued innovation will additionally boost the precision and efficiency of optical fibre evaluation.

Exact measurement of optical fibre size is essential for improving the efficiency and integrity of fiber optic systems. In a significantly linked world, where high-speed data transmission is paramount, the function of exact optical fibre size measurement can not be overemphasized, as it offers as the structure for durable communication framework.When picking an optical fiber size analyser, several crucial features call for careful factor to consider to guarantee optimal efficiency and reliability.Reliable use of optical fiber her explanation size analysers pivots on an extensive understanding of finest practices that boost dimension integrity and accuracy.Exact measurement of optical fibre size is vital for optimizing efficiency and guaranteeing reliability in interaction systems.